- Montegrappa Limited Edition - 2006 and onwards

- Montegrappa Limited Edition - 2001 to 2005

- Montegrappa Limited Edition - pre-Richemont era

- Montegrappa Limited Edition - Anniversario

- Montegrappa Limited Edition - Ferrari

- Montegrappa Organinzer Fountain Pen

- Montegrappa Privilege Pens

- Montegrappa Extra and Extra 1930 Pens

- Montegrappa Miya Argento Pens

- Montegrappa Miya Pens

- Montegrappa Emblema Pens

- Montegrappa Espressione Pens

- Montegrappa Nerouno Pens

- Montegrappa Game of Thrones

- Montegrappa Moon Landing

- Montegrappa Piccola Pens

- Montegrappa Memoria

- Montegrappa Parola

- Montegrappa Ducale

- Montegrappa Fortuna

- Montegrappa Piacere

- Montegrappa Micra Pens

- Montegrappa Ink Well

- MONTEGRAPPA INKS

- Montegrappa Pen Pouch and Case

- Montegrappa Harmony Pens - Retired Models

- Montegrappa Symphony Pens - Retired models

- Montegrappa Classica Pens - Retired Models

- Montegrappa Oriental Zodiac Pens - Retired Models

- Montegrappa Reminiscene Pens - Retired Models

- Montegrappa 300 Series Pens - Retired Models

- Montegrappa Elmo Pens - Retired models

- Montegrappa Eleganza Pens - Retired Models

- Montegrappa BriarWood Pens - Retired Models

- Montegrappa Senna - Retired Models

- Montegrappa Playing Cards

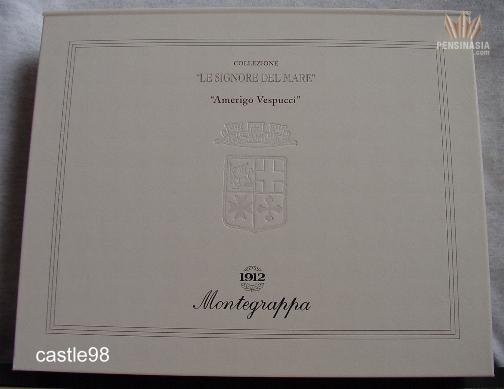

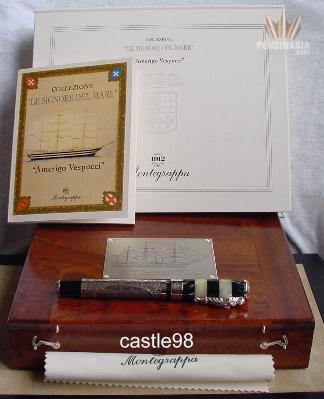

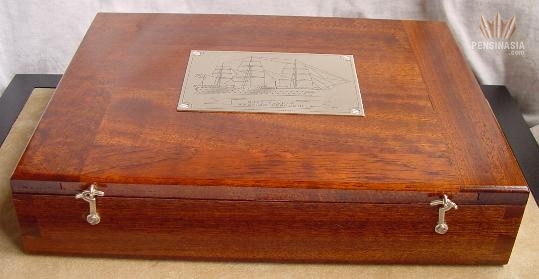

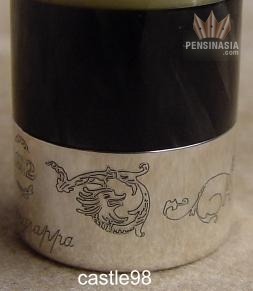

Montegrappa Amerigo Vespucci Fountain Pen

Amerigo Vespucci" fountain pen is manufactured deploying precious materials and jewellery techniques, such as low relief engraving and vitreous enamelling for the pens barrel, and hand-enhanced die casting for the clip. Exclusive techniques that make Montegrappa writing instruments unique and unequalled. Montegrappa a name invariably associated with whenever the art of low relief engraving is mentioned. Unique and the only pen manufacturer to deploy this technique, in 1992 Montegrappa produced the 80th Anniversary pen from which much applause and admiration was received from the general public as well as other manufacturers. Beginning with the subject of design, a pattern is mapped out in the special CAD/CAM System. Thereafter; the designing process becomes the center of concentration as the image to be etched, has to form a continuous pattern around the tube. It is at this stage that the programming of the CAD/CAM plays the crucial and vital role in this technique. Sometimes taking up to months, this tedious and complex process that requires designing, drawing and test-etching is repeated to arrive at the finalised pattern. Any minute mismatching of the pattern can result in disastrous and costly consequences. Matched to perfection, the meeting point where the engraving starts and ends can sometimes be oblivious even to an expert. To deploy the special technique of low relief engraving, a special CAD/CAM System is used to perform all the functions of 2 dimensional engine turning and in addition generates low relief surfaces whereby small amounts of' metal is carved away whilst cutting very fine lines which vary in depth. The 3-D image is recessed out of the surface in a finely scanned pattern. It is not necessary for the path of the tool to be straight in the X-axis, though for most Low Relief a straight line is usually chosen. Precision engineering and consistent quality checks of the end product is required to ensure consistency in the production. With the result of a product only of the finest finishing and quality that can be expected from a process and technique so refine, even "Michael Angelo" would be jealous of Which is why, Montegrappa makes writing a privilege. . . . The Privilege Of A Lifetime. An ancient art that has been preserved for generations since the VI century B. C. This painstaking process was and is still used by silver and goldsmiths as a vitreous material for decoration to enhance their work of art. Appreciated for its wide variety of chromatic ranges and its enduring ability of perfect preservation. The use of enamel has left its mark in history in the periods of greater artistic fertility, from the Egyptians to the Middle ages and the Renaissance to the XIX Century. For greater visual presentation, two effects were created. A giorno" meaning "day", results in the enamel being translucent allowing the background to be seen, and A notte meaning "night", results in an opaque finish with the latter technique being most commonly used. Enamel is composed of finely grind crystal, coloured by metallic oxides that generally leave it translucent which can also be opaque by adding a certain quantity of stain oxides. The object that one wishes to enamel has to be endowed with special features in order to be processed. To create the dramatic colour effect and contrast between dark and light shades, the lower surface is "engine turned" or etched. The edges of the recess to be filled with enamel needs to be chamfered to allow the intricate application as well as the heating process to be conducted. The surface to be enamelled have to be of consistent thickness to withstand the extreme temperatures of this process. In between multiple coats of enamel being applied with a brush, the object is heated at temperatures between 750 to 830° C until the enamel melts and fuses itself to the object. This time consuming and tedious process is repeated for each different colour used until the completion of the design is achieved. Using a special tool made of carborundum, the finished design is then filed to obtain a perfectly smooth surface and polished with brushes of felt and pumice. Ultimately to protect the finished masterpiece, the whole process is repeated with a thin layer of transparent enamel. The incredulous patience needed for this tedious, time consuming, labour intensive and intricate work of art, showcases the superlative creativity of craftsmanship embodied in a masterpiece to be treasured for generations. Die-casting" or sometimes referred to as "lost waxed casting" has been a process used extensively since the fifth century the process has changed very little since that time. The multiple stages of work involved in die casting is mountainous that one would rarely consider venturing into this business if not for the field of specialisation. To begin, a hand carving of a three-dimensional sculpture, like of the pen is encased in a plastic "dough" which dries to a rubberlike mould. Then a zic-zac incision is made at the side and the sculpture is removed. With a special vacuum wax injection machine, the air is 'sucked and melted wax is injected into the mould, creating an exact replica of the sculpture. After hardening, multiple replicas are affixed to a "tree" at a time , encased in plaster and heated in an special oven. The wax melts and drains from a hole in the cast at 180° Celsius before it is hardened at temperatures as high as 750° Celsius. Each plaster cast can only be used once. Thereafter; cooling to 600° Celsius, molten silver or gold is poured the plaster cast and left to sit for 15 minutes and then plunged into water. The process cracks the plaster exposing the sculptures. At this point, the experience of a skilled craftsman takes centre stage and small details which might have been lost in the casting process are redefined by hand. The 'antiquing" and polishing of the sculpture to its refined look, forms the final stages of the die-casting process. It is with great anticipation when each piece of die-cast pen goes through a long and tiresome process to unveil a timeless art deserving of such acclamation and a place in the showcase amongst other collectibles.

Interested in this pen?

Buy This Pen Now

Please contact me using the form to the right if you are interested in buying this item. I will need to check my stocks before getting back to you :)